"StudyStudyStudy" (jesterjin)

"StudyStudyStudy" (jesterjin)

04/19/2016 at 16:25 ē Filed to: None

4

4

12

12

"StudyStudyStudy" (jesterjin)

"StudyStudyStudy" (jesterjin)

04/19/2016 at 16:25 ē Filed to: None |  4 4

|  12 12 |

Moving onto other pieces.

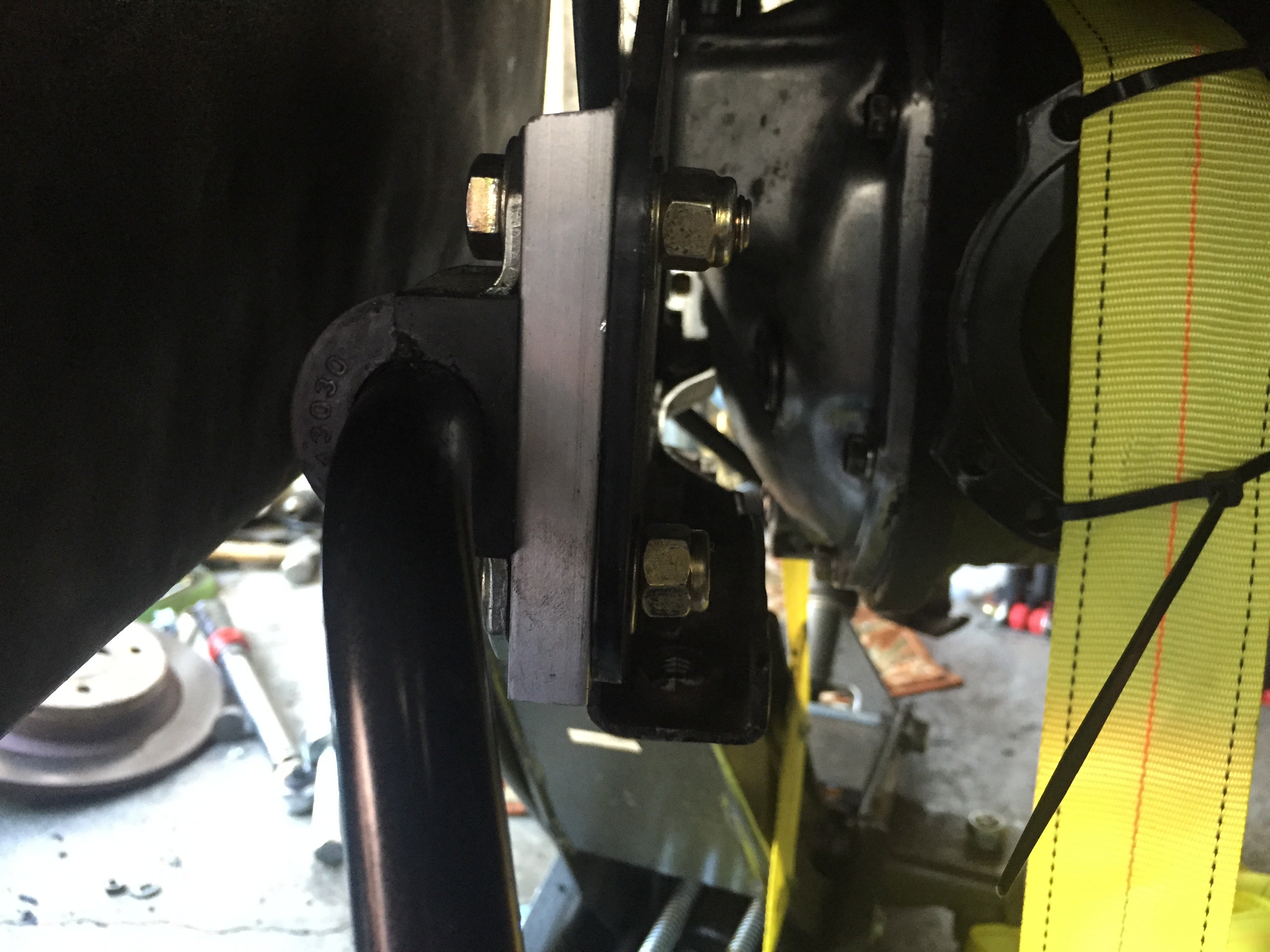

Cut out and drilled holes to make these aluminum spacers for the sway bar mount.

Figured out the hard way that the punch in lock nuts donít work that well with the axle adapters. The extra height makes it difficult to hit the side of the nut. Managed to fold it a little bit. Hopefully it holds. Note to self and others, if getting 280zx adapters, just get the 280zx lock nut. Iím going to pickup an actual punch instead of a screw driver to retry later this week.

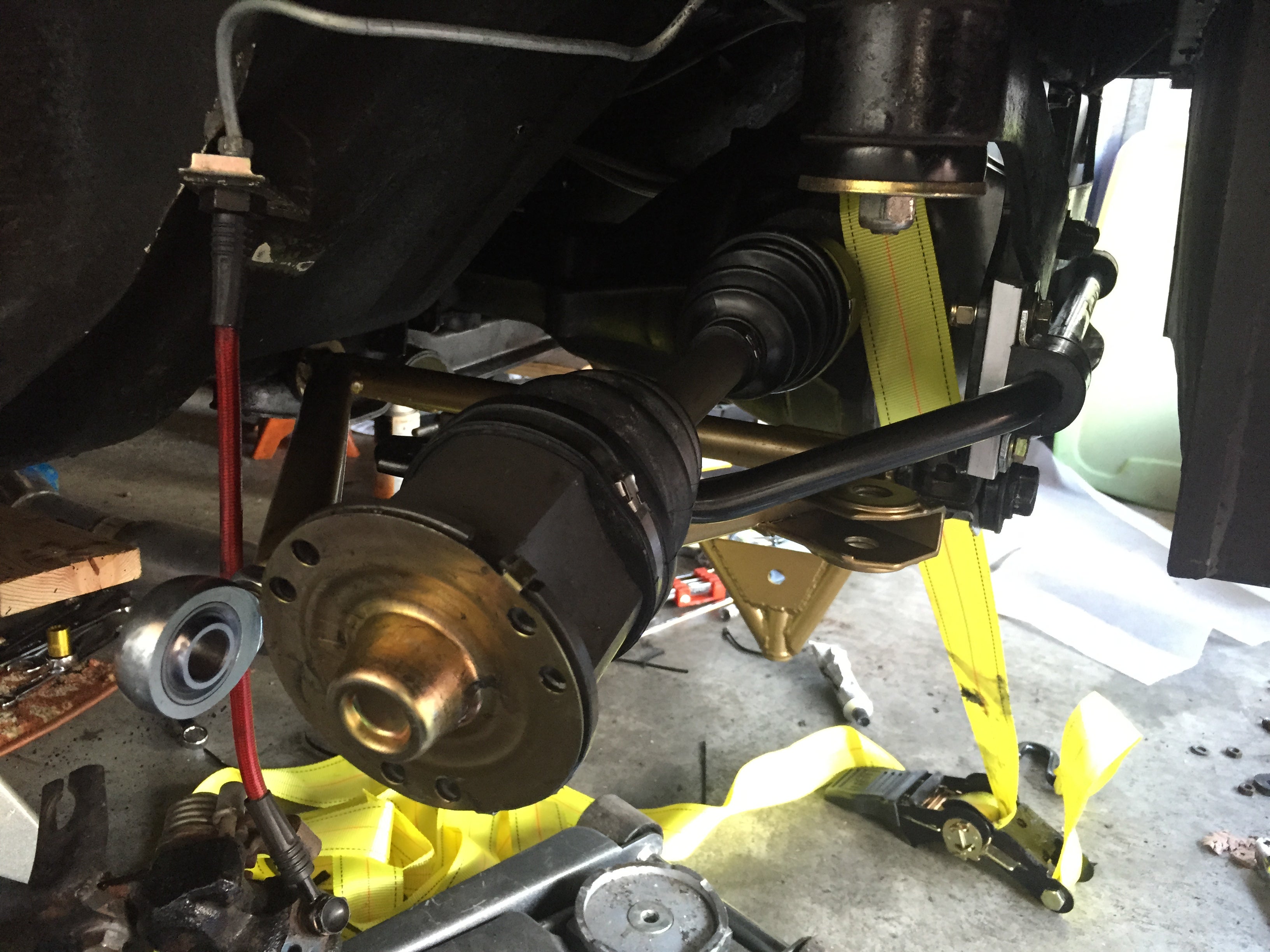

Assembled the upright in the final form. Put in the coilover inserts with plenty of anti seize.

Got the control arms installed, clamping the rear loosely, then the brace in the front. Followed by tightening everything down with lock tite.

Then I installed the uprights, a little help with the jack and it lined up easily enough.

With the sway bar spaced back and the Rear Lower Control Arms put on you can see why the spacer is needed. Much better alignment.

Getting awfully close now.

The problem at the moment is that the replacement bolts for the axle are 13mm heads instead of 12mm head, a strange american standard to up the head size on metric bolts. Turns out the extra mm makes it impossible to slip in the correct wrench to tighten them. Just placed an order for plain old hardware in JIS (Japanese Industrial Standard), AKA bolt head sizes that make sense. Also ordered some allen button and regular allen head bolts as one, they come in a higher grade, and two the button head may be required for clearance on the passenger side. If I go through the trouble of removing all the bolts for the hangers for the RLCA and the differential, the next time through there wonít be a re-used bolt left. All new hardware.

Combined with the recent trip to fastenal, Iíve spent $200 on bloody hardware just redoing the rear end. Just bolts, washers, nuts...

Three more pieces of the puzzle left to figure out now, welding the passenger axle, re-building the sway bar end links, and removing the rust from the rear calipers. The rest will be a matter either replacing the part (SS brake line), and some piece of mind, rust proofing/treating, rerouting the brake line.

Lessons learned:

You will always forget something, that is for sure.

Internet advice is sometimes very good advice (forum member suggested the sway bar spacing)

Expect things to go wrong, I suspect of the three remain puzzle pieces, all three will prove challenging.

Money Spent:

110 - misc hardware for rear end

Subtotal : 110

Total spent: 21863

!!! UNKNOWN CONTENT TYPE !!!

MUSASHI66

> StudyStudyStudy

MUSASHI66

> StudyStudyStudy

04/19/2016 at 17:44 |

|

Wow!!! $22000 spent on that car.

Have you tracked the hours youíve spent on this?

When you first bought it, what was your original plan and budget?

Do you ever regret doing it?

Amazing work btw, it seems you poured your heart and soul into this (not to mention time and dollars).

itschrome

> StudyStudyStudy

itschrome

> StudyStudyStudy

04/19/2016 at 17:47 |

|

this has been running so long I kind of forget what kind of car it is minus some sort of Z.... or what it looked like to start... which is awesome cause Iím gonna go back to the start again and read them all! I love build threads. partly because itís fun to watch and partly because I could never do it myself so I live through them a bit..

StudyStudyStudy

> MUSASHI66

StudyStudyStudy

> MUSASHI66

04/19/2016 at 18:28 |

|

I did an exercise where I tracked the hours I put into just the toyota engine swap portion. From when I got the engine to when I pulled out of the garage, it was like 200 hours. Getting the engine in was done in about 4 hours. Getting everything else, all the small things and stuff, that seems to always take the longest. Iíve spent days just kind of organizing, cleaning, planning, it is something to think about. Total hours is probably too embarrassing to calculate.

Original plan was to clean it up, paint it, drive it, swap something into it. Had a few setbacks. Budget was what I had to my name. I probably wasnít planning on going over 10k.

Oh yea, regrets come and go. Especially when my daily driver died, the thought that I had 20k+ invested into a car I couldnít drive was painfully apparent. Still this gets me entrance into a lot of things, event wise so hopefully I get to reap a few benefits this year. Plus just problem solving was a big help. Being able to look at something and figure out what is wrong and the options to fix it. If the problem is something wrong with a car or mechanical device, I can usually fix it now vs having to google or find a video tutorial on the subject.

StudyStudyStudy

> itschrome

StudyStudyStudy

> itschrome

04/19/2016 at 18:34 |

|

Yea car is covered in parts and boxes, I hardly recognize it at the moment. I canít wait to get it out in the sun again and maybe give it the first car wash Iíve ever given it. The new ride height is also going to be a hoot as well.

Hope you enjoy, let me know if you come across any problems, I try to go back and edit some of the older posts for continuity, those were really rushed out quickly on a daily basis, so lots of typoís and odd formats.

Even with a big build, I still live vicariously through others, nearly all my youtube subscriptions are car related/build related. You would be surprised how much you can pick up. I took apart and fixed a 4 barrel carb without ever having touched one just based off memory from a motor trend video. My two closest friends also have builds that I check in on once in a while, it is fun seeing things come to life.

uofime-2

> StudyStudyStudy

uofime-2

> StudyStudyStudy

04/19/2016 at 22:52 |

|

I ran into that same stupid problem with the different bolt sizing standards on my WRX. Ended up rigging something to work from homedepot and then going to the dealer to get the right parts later. Funny thing is I think the hardware from the dealer was actually cheaper than the stuff I got at HD!

StudyStudyStudy

> uofime-2

StudyStudyStudy

> uofime-2

04/19/2016 at 23:16 |

|

Lol, I think that may be a first!

I decided I did not want to deal with it for quite a while so I ordered quite a flew extras.

uofime-2

> StudyStudyStudy

uofime-2

> StudyStudyStudy

04/19/2016 at 23:26 |

|

Definitely file that one under lessons learned, dealer parts counter is in fact affordable and the people that work there are very helpful.

If I had the space and money I would have a massive stockpile of assorted hardware.

StudyStudyStudy

> uofime-2

StudyStudyStudy

> uofime-2

04/20/2016 at 13:35 |

|

Dealerships and service departments are usually bad.

Part counter guys are usually helpful and friendly!

A friend of mine took apart a few late model cars and just shelved all the bolts. Sometimes it is better to go over to his house versus the hardware store lol.

DynamicWeight

> StudyStudyStudy

DynamicWeight

> StudyStudyStudy

04/20/2016 at 14:38 |

|

I just finished reading through this whole build log. I have to say, itís so much more fun since youíve kept such good track of everything. I love reading logs and usually there is a lot of hand waving when it comes to money and such. Itís really fascinating to see it all added up. I think a lot of people would be surprised to find their own hobbies add up to the same.

Itís the same for me with my RC car. People ask how much it cost... ďThatís complicatedĒ

StudyStudyStudy

> DynamicWeight

StudyStudyStudy

> DynamicWeight

04/20/2016 at 16:35 |

|

Thanks for slogging through all that, hopefully not too much of a bore.

It was a pet peeve of mine when someone did build logs that didnít have pictures and a lot of magic happened behind the scenes. I think the money aspect is the only one I have been more or less different to others, kind of interesting that I can give pretty hard estimates now of how much I spent. Not comprehensive of course, and quite a bit of it is on tools, but still kind of fun to see it all written down.

DynamicWeight

> StudyStudyStudy

DynamicWeight

> StudyStudyStudy

04/20/2016 at 16:55 |

|

It wasnít a bore at all for someone who is interested in this sort of thing. Your straight forward writing style and humble acceptance of mistakes made it really enjoyable. Not just enjoyable but inspiring. I have always thought of welding as some sort of black majicks, but the more I read stories like yours and others, the more I think itís something I could do.

StudyStudyStudy

> DynamicWeight

StudyStudyStudy

> DynamicWeight

04/20/2016 at 18:56 |

|

Oh definitely, anytime I start to think I may know about something I realize there is always more to study and more to learn.

I cannot recommend enough to learn welding. It really is one of those skills that it takes 30mins to an hour to learn and you can spend a lifetime to master. You just have to not let it run away from you, know your limitations, recognize when you are struggling, and also recognize when the task is just hard. You can probably snag a lesson from a local community college or even a craigslist welder as long as they are established. I really love teaching welding, Iíve taught a terrible welder how to put down a good bead in 10 mins just based off sound, Iíve taught a female coworker how to build a table in an hour. Iíve made things for people that just had an idea in their head and never thought it would be possible to execute, Iíve repaired strange and specific things that would have cost an unreasonable amount elsewhere.